CHAMBER PIPELINE

BELLOWS FOR A

CHEMICAL PLANT

Chemical plant

Chemical plant

Europe

Europe

EJMA

EJMA

As per client request Belman has engineered and manufactured these very special Chamber Pipeline Bellows. They are installed in a pipeline that carries sulfur in a chemical plant in Europe.

CLIENT ISSUE

The client turned to Belman for a special Piping Bellow design. To ensure that the sulfur media in their pipeline did not solidify, the client needed to keep the temperature of the medium at a sufficiently high level. A chamber design could solve this, which is why the client needed an experienced manufacturer that was able to design and produce the very special Chamber Pipeline Bellows for them.

BELMAN SOLUTION

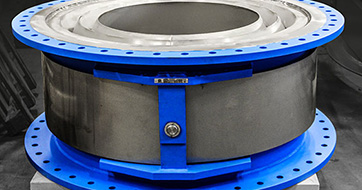

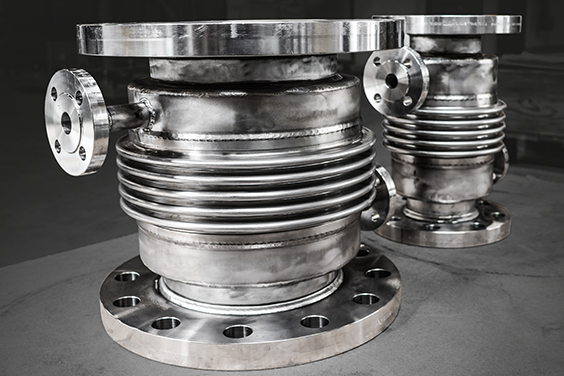

Chamber Pipeline Bellows

The Expansion Joints – a pair of Chamber Pipeline Bellows – were designed completely from austenitic stainless steel (EN 1.4571 and EN 1.4404), due to the operating conditions. They were designed with the characteristic bellow around another bellow. Chamber Pipeline Bellows are used to make it possible to increase the temperature of the media and thus improve the flow. The Chamber Expansion Joint is a design where the Expansion Joint has another Expansion Joint around it, whereby a chamber is formed between the two. In this closed chamber a media is heated and flows through the chamber via an inlet and an outlet respectively. On its way through the Expansion Joint, the heating medium emits heat to the inner Expansion Joint. In this way, the media (in this case sulfur) that flows in the inner bellow maintains/increases the temperature, which in turn increases the fluidity of the medium, thereby preventing the sulfur from solidifying.

Belman – expertise on Jacketed Pipeline Bellows designs

Chamber Expansion Joints are also known as Jacketed Expansion Joints or Jacketed Pipeline Bellows. Chamber Pipeline Bellows are widely used in chemical plants as well as in many other applications. Due to the nature of the media in these industries, Chamber Expansion Joints are manufactured in all types of steel materials, including high-alloy steels. Usually, the material is determined by the temperature as well as the type and consistency of the medium. If the medium is very corrosive, high-alloy materials are often used. The surroundings of the Expansion Joint may also influence the choice of material.

DESIGN FEATURES

Design parameters of the Chamber Pipeline Bellows:

Type: Chamber Expansion Joint • Quantity: 1 pc. • Dimension: DN 100 • Installation length: 350 mm • Medium: Sulfur/Steam • Design pressure: 5 barg • Design temperature: 200°C • AX: +/-30 mm • Bellow: 1.4571 (AISI 316Ti) • Pipe ends and flanges: 1.4404 (AISI 316L) • Design code: EJMA

Type: Chamber Expansion Joint • Quantity: 1 pc. • Dimension: DN 200 • Installation length: 350 mm • Medium: Sulfur/Steam • Design pressure: 5 barg • Design temperature: 200°C • AX: +/-30 mm • Bellow: 1.4571 (AISI 316Ti) • Pipe ends and flanges: 1.4404 (AISI 316L) • Design code: EJMA

CLIENT BENEFIT

- Elimination of the problem of sulfur solidifying and, at worst, the risk of media packing up in the bellow convolutions

- Trouble-free operation

- Option of increasing the temperature of the sulfur (the media) in the inner bellow and thus easing the flow of the media

- The optimum Pipeline Bellows for the application

- Assistance from an Expansion Joint manufacturer with vast experience in special Expansion Joint designs

RELATED INFORMATION

TECHNICAL information

- Technical information on Chamber Expansion Joints in the Expansion Joint Catalogue on

pages 33 - Technical information on media, and its influence on Pipeline Bellows design, is available in the Expansion Joint Catalogue on

pages 410-411

REFERENCES

PhosAgro • Air Liquide • ICL • Cabot Corporation • Unilever • Schenectady Europe • Metafrax • Johnson Formox • OCI • Solvay • SASA • IBN Sina • Xstrata • SABIC • Ineos • Mexichem • BASF • Borsod chem • ENI • Messer Group • Croda • Nouryon • Swecem • SILA • Dow • CF Fertilizers • SSAB • Kronospan • Wanhua • Perstorp • FMI Process • Dovechem • Masisa • Norcarb • Adama • Sasol • SIBUR • BAGFAS • Norcarb • Nouryon • Celanese • KGHM • Aurubis • Pfizer • Haldor Topsoe •