HASTELLOY C-4 BELLOWS

FOR HEAT EXCHANGERS

Petrochemical plant

Petrochemical plant

China

China

ASME VIII Div.2:2021

ASME VIII Div.2:2021

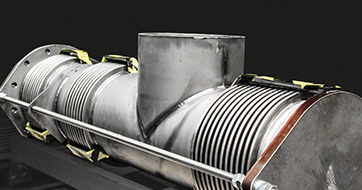

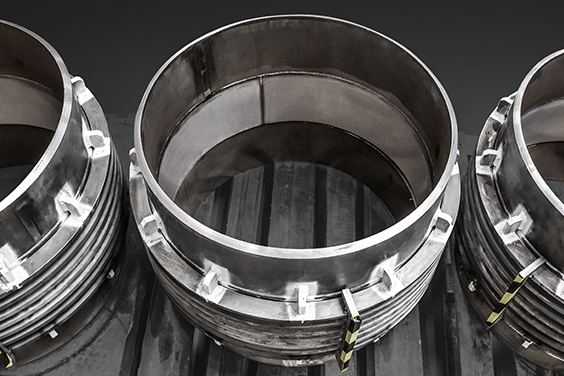

For heat exchangers installed in a petrochemical plant in China, Belman has designed, manufactured and performed extensive testing on five Ring Reinforced Expansion Joints made from Hastelloy C-4. The special Hastelloy C-4 material, the design code version used as well as the extensive testing were all crucial for the client.

CLIENT ISSUE

The Bellows were produced according to special requirements as they needed to operate under high pressure in a petrochemical plant. Naturally, that resulted in extensive testing of high-pressure Expansion Bellows, including pressure tests under 71.3 barg. The client also needed the calculations for the Hastelloy C-4 Bellows to be done in accordance with ASME VIII Div.2:2021. ASME codes are widely used in the petrochemical sector and ASME VIII is known for being more conservative with its life cycle calculations. Last but not least, the only material that was suitable for the Bellows was Hastelloy C-4. The client turned to Belman as we are one of very few manufacturers that are able to source this material and have it in stock. What’s more, Belman also have vast experience in producing Expansion Joints from this very special alloy. Not only that, but we were more than capable of helping the client fulfil their other requirements.

BELMAN SOLUTION

Meeting many client requests, including a very special material

In accordance with the client’s requirements, the Ring Reinforced Bellows were made from Hastelloy C-4, which is a nickel-chromium-molybdenum alloy with outstanding high temperature stability as well as high ductility and corrosion resistance. This makes it suitable for use in the chemical and petrochemical industries. Given Hastelloy C-4 is designed to have outstanding corrosion resistance, it makes a great choice for all moderate to severe corrosive environments where product service life is important. Therefore this material is widely accepted by plant operators and maintenance specialists, who appreciate Hastelloy C-4’s toughness and ability to withstand very aggressive fluids. Belman keeps this special material in stock and is experienced in working with it.

The inner sleeve was made from 1.4541 (AISI 321), which is sufficient if the inner sleeve is not subjected to stress while in contact with the media. If the inner sleeve is likely to come under stress while in media contact, Hastelloy C-4 would be the optimum solution for the inner sleeve.

Extensive requirements for NDT

As per the client’s requirements, the Expansion Joints have undergone extensive NDT testing, including 100% X-ray (radiographic test) and 100% liquid penetrant testing (PT) on all attachment welds (this can be seen on the photos as well), Hydrotest at 71.3 barg witnessed by a notified body, leak testing and magnet testing (MT) as well as positive material identification (PMI). As per the client’s requirements, full documentation via the Belman MDB (Manufacturing Data Book) was supplied; this included all the reports on the NDT tests that were performed, drawings, materials certificates, welding plan etc.

Belman: Extensive requirements for NDT

Since 1994, Belman has expertly designed and produced Expansion Joints for various applications, installation points and countries. This expertise and craftsmanship also includes the production of high-end Expansion Joints from high alloy materials, which makes Belman the go-to company for special alloy Expansion Bellows. Belman holds a large stock of both standard austenitic steel materials as well as many other special alloys besides the Hastelloy C-4 used in this case, such as Hastelloy C-22, Duplex, Super duplex, titanium, Inconel, Incoloy, Monel and many others.

DESIGN FEATURES

Design parameters of the Hastelloy C-4 Expansion Bellows for heat exchangers:

Type: Ring reinforced Expansion Joints • Quantity: 5 pcs. • Dimensions: DN 700 • Installation length: 635 mm • Medium: – • Design pressure: -1/+50 barg • Design temperature: 230°C • AX: +38/-5 mm • Bellows: 2.4610 (Hastelloy C-4) • Inner sleeve: 1.4541 (AISI 321) • Pipe ends, reinforcing rings: SA-516 gr. 70+N • Design code: ASME VIII Div.2:2021

CLIENT BENEFIT

- Assistance from a producer with the capacity and financial clout to hold a large stock of special alloys to supply clients with special needs.

- Expansion Joints designed by a supplier with vast experience of ASME design codes

- Expansion Joints designed by a supplier skilled in the production of Bellows from special alloys

- Custom-designed Expansion Joints to meet the exact needs and requirements of the client

- Safe and efficient accommodation of movements under high pressure

- Trouble-free operation and longer service life of the Expansion Joints, as the material is highly resistant to the specific media and surroundings

RELATED INFORMATION

TECHNICAL information

- Technical information on materials for Expansion Joints and their properties in the Expansion Joint Catalogue on

pages 51-55 - Technical information on Ring Reinforced Expansion Joints in the Expansion Joint Catalogue on

page 379

REFERENCES

PhosAgro • Air Liquide • ICL • Cabot Corporation • Unilever • Schenectady Europe • Metafrax • Johnson Formox • OCI • Solvay • SASA • IBN Sina • Xstrata • SABIC • Ineos • Mexichem • BASF • Borsod chem • ENI • Messer Group • Croda • Nouryon • Swecem • SILA • Dow • CF Fertilizers • SSAB • Kronospan • Wanhua • Perstorp • FMI Process • Dovechem • Masisa • Norcarb • Adama • Sasol • SIBUR • BAGFAS • Norcarb • Nouryon • Celanese • KGHM • Aurubis • Pfizer • Haldor Topsoe •